Tel:0512-66958483

Email:engforlife-mkt@www.efl-tech.com

Alginate Methacryloyl (AlgMA) ; EFL-AlgMA-50K/300K

The kit includes alginate methacryloyl and photoinitiator LAP.

All products in the AlgMA range can be used in cell culture, biological 3D printing, tissue engineering, etc.

This product is for research use only and should not be used in humans.

Salesperson:Panpan Wang(EFL)

Phone:15335258233

Email:engforlife-mkt@efl-tech.com

Foreign distributor:ANR Technologies Pte Ltd

Sodium alginate (Alg) is a linear polyuronide polymer composed of β-D-mannuronic acid and α-L-guluronic acid, which has good biocompatibility and has been widely used in a variety of medical applications such as cell encapsulation and drug sustained release.

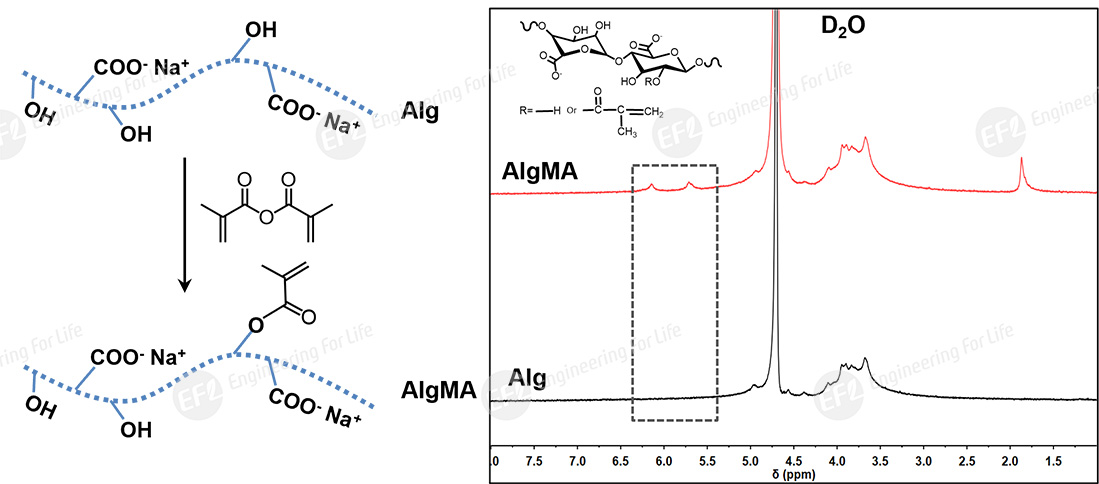

Alginate Methacryloyl (AlgMA) obtains the photocuring ability by introducing methacryloyl groups into the chain of sodium alginate molecules. Compared with the traditional bivalent ion (calcium ion, etc.) crosslinking, the photocuring crosslinking method has high portability and good homogeneity within the gel. Material systems based on AlgMA have been widely used in many biomedical research fields, including: tumor model construction, cell loading, wound dressing, drug controlled release, dental impression, etc. In addition, both -OH and -COOH in sodium alginate structural units can be used as chemically active sites to introduce more active groups through chemical modification, and have a three-dimensional (3D) structure suitable for cell growth and differentiation, thus giving it new properties (cell adhesion, active drug loading, etc.), and expanding its tissue engineering applications.

The AlgMA product from EFL team (EFL-AlgMA series) has stable physical and chemical properties through strict raw material screening and quality testing. It can be cured within 20 seconds with visible light irradiation, has good biocompatibility, strong material scalability, and can provide a variety of viscoelastic properties to adapt to different application. AlgMA can be combined with GelMA and HAMA hydrogels from EFL to better simulate the microenvironment of bone, cartilage, skin and other body tissues, and obtain better cell 3D culture and bio-ink.

Cell culture, bio 3D printing, tissue engineering, etc.

Dry kit: room temperature, 3 months; 4℃, 12 months; -20℃, 18 months.

Fig 1. Synthesis reaction mechanism and NMR spectrum of AlgMA

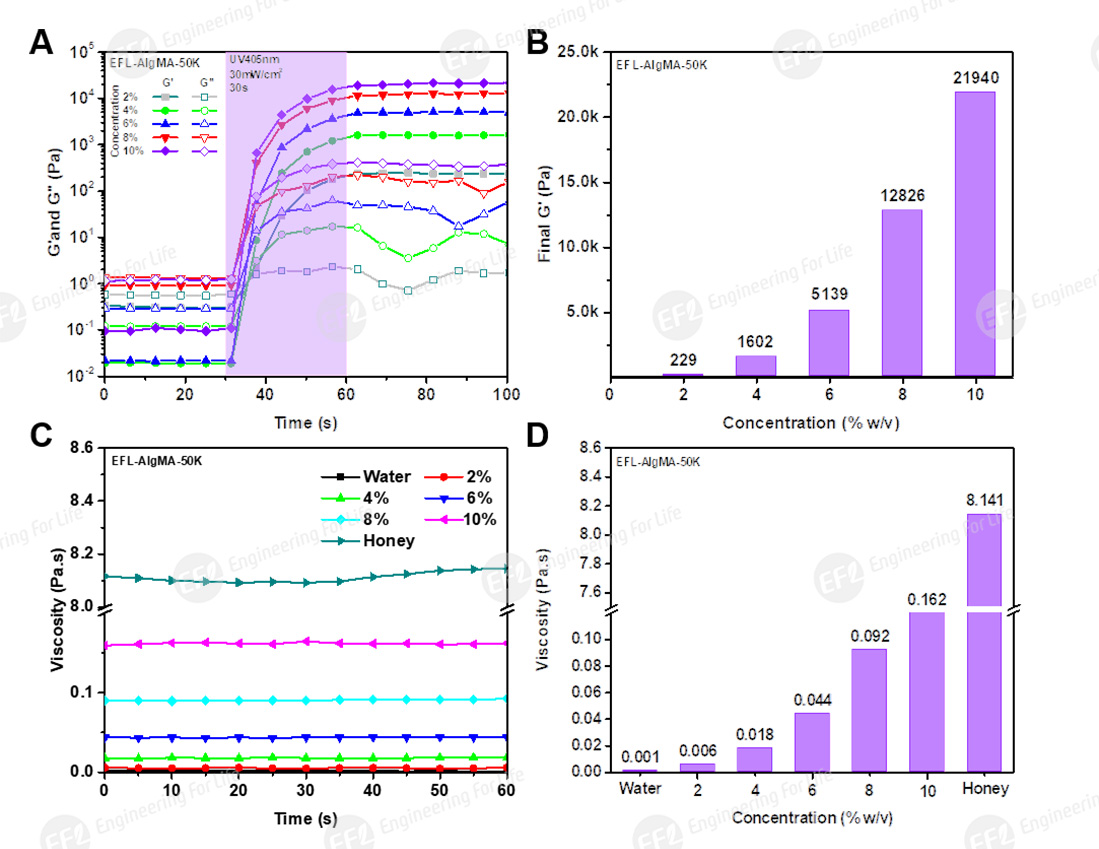

Fig 2. Rheological properties of AlgMA-50K at different concentrations: (A) photocrosslinking process; (B) storage modulus G’ after curing; (C, D) viscosity

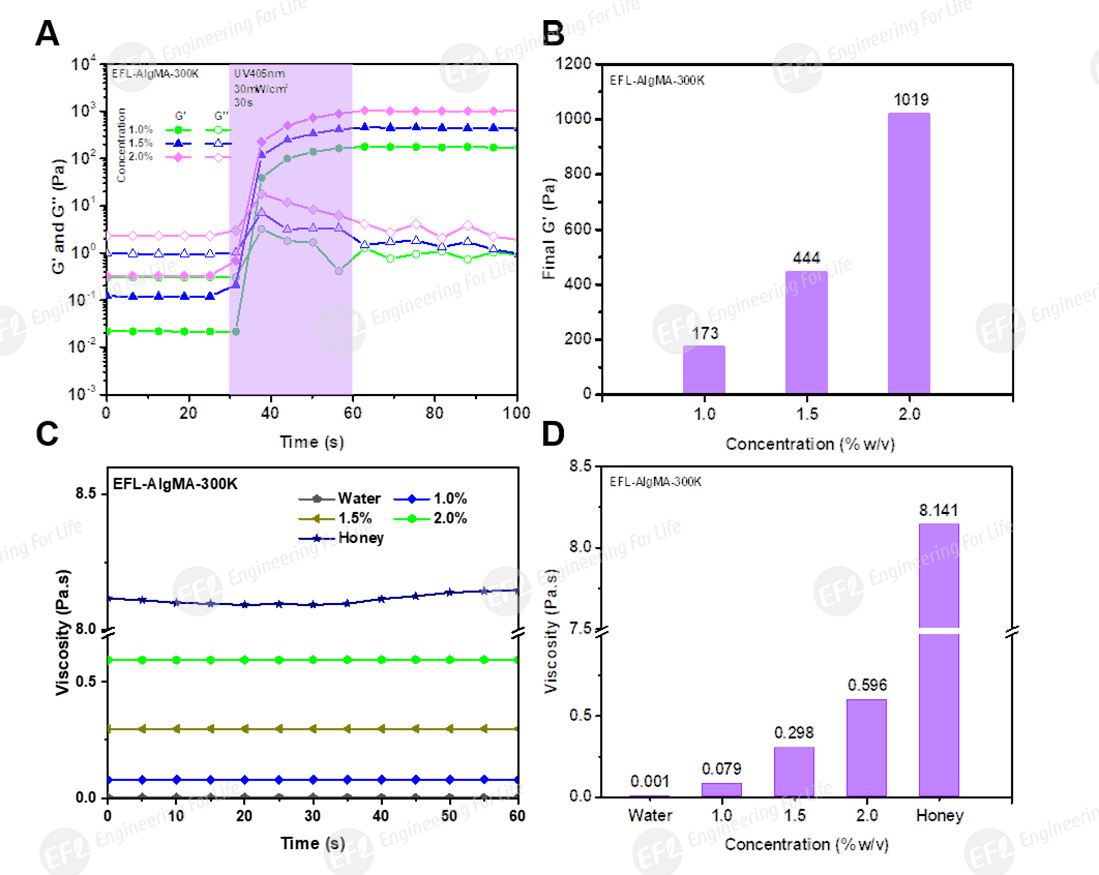

Fig 3. Rheological properties of AlgMA-300K at different concentrations: (A) photocrosslinking process; (B) storage modulus G’ after curing; (C, D) viscosity

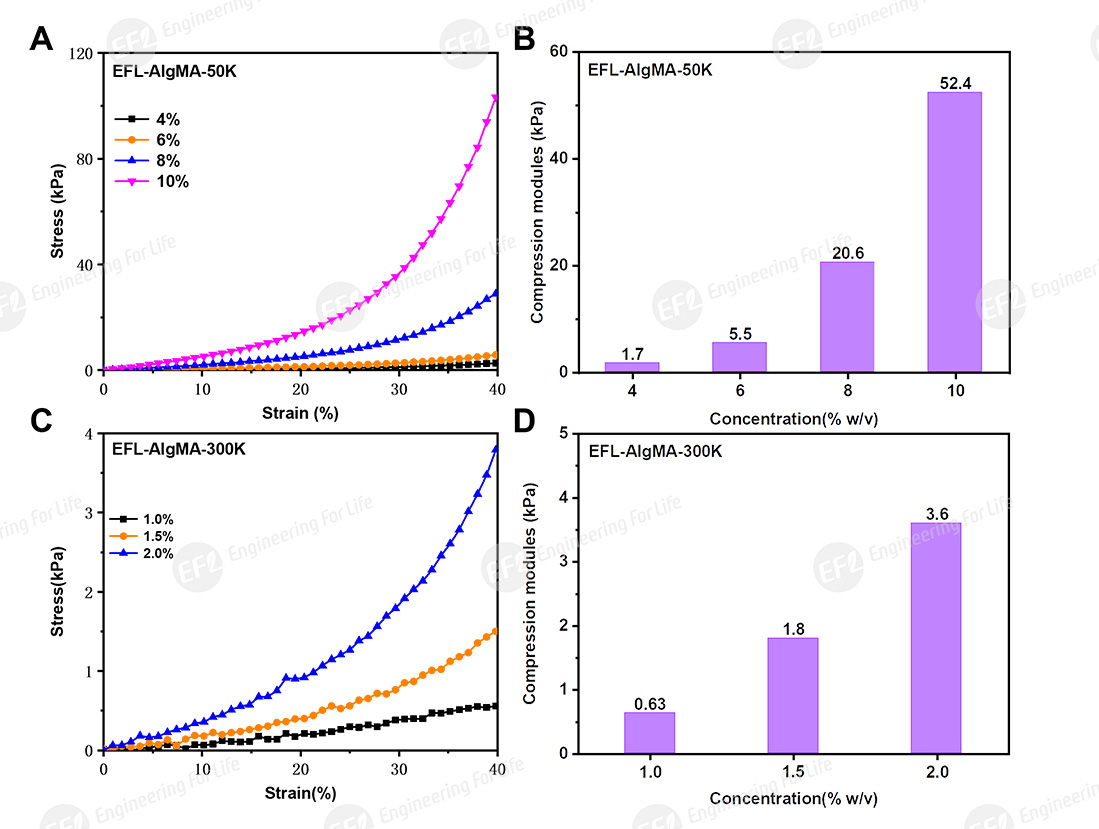

Fig 4. Compressive properties of AlgMA-50K/300K at different concentrations (UV405nm, 30mW/cm², 30s) : (A,C) stress-strain curve; (B,D) compression modulus

The introduction of methyl propylene group, AlgMA can realize the dual crosslinking performance of ionic crosslinking and photo crosslinking, and enhance the mechanical properties of AlgMA composite hydrogels. EFLer uses gelatin (EFL-GEL-001) as an auxiliary bio-ink for extrusive 3D bioprinting, and with the EFL-BP66 series multi-functional extrusive bio-3D printer of EFL, printing based on sodium alginate hydrogel grid scaffolding can be realized. Specifically, the Alg/Gel based grid scaffold is only formed by Ca2+ crosslinking, while the AlgMA/Gel grid scaffold is simultaneously crosslinked by Ca2+ and UV photocrosslinking. Tests show that AlgMA/Gel mesh scaffolds have better forming fidelity and enhanced mechanical strength compared with Alg/Gel at the same concentration (Fig 5. a/c).

In addition, after soaking in Na2CO3 (2% w/v) solution for 15min, the Alg/Gel grid scaffold is more prone to fracture after Ca2+ dissolved from the gel network, while the AlgMA/Gel grid scaffold remained intact (Fig b).

Fig 5. AlgMA/Gel and Alg/Gel grid scaffold printing bracket molding fidelity and mechanical strength display: (a) 3D extrusion printing process; (b) grid support after soaking in Na2CO3 (2% w/v) solution for 15min; (c) compression modulus test diagram and stress curve

Fig 6. AlgMA hydrogel 3D cell (HUVECs): observation on day 1 after inoculation

【EFL-AlgMA series】-Alginate Methacryloyl